Crude palm oil contains a lot of water, as well as colloid, pulp and other impurities, which must be remove. Otherwise, it is easy to cause the fermentation hydrolysis of palm oil and increasing of free fatty acids. Traditional palm oil purification equipment includes oil tank, drying oven and filter press. This kind of equipment combination is complicated, costly and needs large space occupation, making it unsuitable for small scale palm oil extraction production.

By the main process of sterilizing, digesting and oil pressing, we can get Crude Palm Oil (CPO) and Palm Expeller (PE).

During digesting process, the palm kernels are separated from the fruits (palm kernel recovery). We can get Crude Palm Kernel Oil (CPKO) and Palm Kernel Expeller (PKE) through process of crushing and oil pressing.

Palm oil has the highest oil yield than other oil crops and it is known as “The King of World Oil”. The main products are palm oil and palm kernel oil, which are widely used as edible oil and industrial oil. Nowadays, the development of small palm oil processing machine has been boosted.

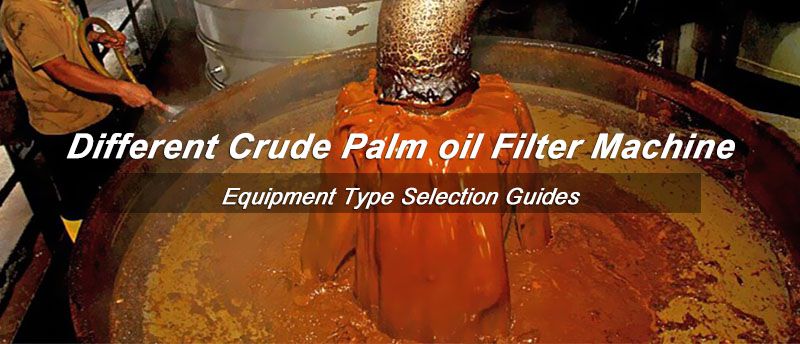

Selection of Crude Palm Oil Filter Machine

With the development of palm oil processing technology, there are various kinds of oil purifier and oil filter press. Their functions and application fields are also different. Now, let’s focus on how to select the most suitable crude palm oil purifier or filter press according to the characteristics of palm oil expelling or squeezing. (Related Equipment: Small Crude Palm Oil Refining Equipment Set for 1-30TPD production )

-

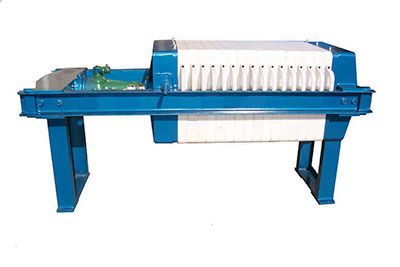

Traditional Filter Press

Tips: As the crude palm oil contains lots of impurities, the filter cloth needs to be replaced frequently, and replacing the filter cloth needs to stop operation. The operation process is relatively tedious. Besides, during the filter pressing process, the filter cloth can only absorb a small amount of water in the oil, and cannot effectively reduce the moisture content. Therefore, traditional filter press are not suitable for palm oil filtration.

-

Vacuum oil-filter

Tips: When the filtering cloth absorbs too much impurities, the pressure in the vacuum tank will increase, and the filter paper needs to be replaced in time. Due to the high impurity content of crude palm oil, this type of filter press machine also needs to change the filtering cloth frequently, which is not good for continuous operation.

-

Multi-function Oil filter Machine

Tips: Although palm oil can be completely purified, but it also faces the need to replace the filter, and expensive, and not suitable for small oil processing workshops.

-

Centrifugal Oil Filter

Tips: Centrifugal oil filter machine is easy to operate, with high safety and competitive price. It is suitable for both small scale and large scale palm oil processing factories. However, the filtered oil may contain a small amount of water and pulp.

To sum up, all kinds of oil filtering machines have different characteristics. They have different advantages and disadvantages for crude palm oil filtration. In order to get purified palm oil, vacuum oil filter and multi-function oil filer is suggested. If the budget is limited, vacuum oil filter should be a good choice, which also matches with small palm oil processing equipment.