In the construction of palm oil mills in Indonesia, a reasonable palm oil factory plant and equipment layout design is crucial for improving production efficiency and operational safety. Proper equipment layout not only affects the ease of maintenance and repair, but also has a profound impact on the construction investment and economic efficiency. Therefore, before starting a palm oil mill business in Indonesia, it is important to fully understand the information related to palm oil mill layout design.

Professional Palm Oil Mill Plant Designer and Machinery Manufacturer/Supplier

Professional Palm Oil Mill Plant Designer and Machinery Manufacturer/Supplier

Learning More Knowledge about Indonesian Palm Oil Mill Setup>>

ABC Machinery is a company with more than 20 years of experience in palm oil mill project construction and manufacturing, we can provide you with professional technical support regarding the construction of the mill according to your actual situation, including, of course, the design of the layout of the plant and equipment. Feel free to contact us!

Navigating Palm Oil Mill Plant Machinery Layout: Well-Designed Steps(by Process)

Palm oil manufacturing equipment layout design should follow the order of the palm oil production process flow, the selected equipment should be reasonably arranged in the workshop to ensure smooth production. Below are some suggestions for general palm oil mill production equipment layout design:

(These recommendations can be adapted on a case-by-case basis and are best discussed in depth with our professional plant designers and engineers early in the design process.)

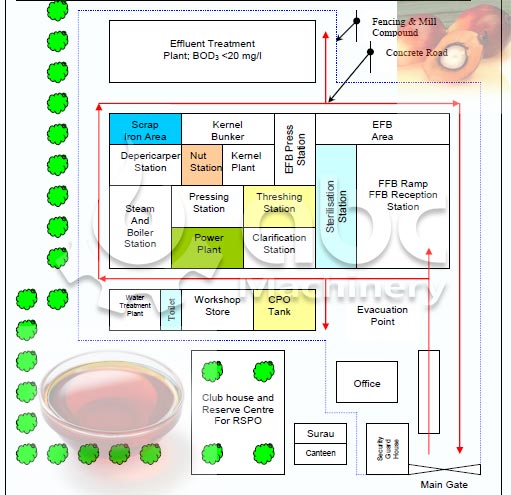

Reference Diagram of A Palm Oil Mill Area Layout Design

Palm Fruit Receiving and Storage Equipment Layout

1. Located At The Entrance Of The Plant

Design the receiving area at the entrance of the palm oil factory for easy unloading of fresh fruit bunches (FFB).

2. Distribution Along The Production Line

Raw materials storage areas can be distributed along the production line to ensure proximity to the line to reduce transportation costs. Ensure that there is adequate access between storage containers so that handling equipment can easily enter and exit.

Related Post: Palm fruit reception system>>

Palm Fruit Pre-Treatment Area Layout

1. Near The FFB Reception System Area

The pre-treatment area is placed near the FFB receiving area and includes sterilizing station, threshing, digester system etc. to ensure a high-quality output of palm oil from thefruit.

2. Optimize The Operation Path

The layout needs to optimize the operating paths to ensure a smooth flow of raw material into the pre-treatment equipment and conveyance of the treated raw material to the next stage of production via conveyor belts or other conveying systems.

Related Post: Sterilizing Station>>; Threshing system>>; Digester system>>

Palm Oil Pressing Extraction Machinery Layout

1. Located In The Center Of The Production Area

The palm oil processing machine should be arranged in the middle of the production line, so that the front and back processes can be smoothly connected, including screw palm oil presses, oil expeller and other key equipment.

2. Along The Sequence Of The Processing Flow

The layout of the production line should consider the flow path of the palm oil and be equipped with palm oil filtration equipment, centrifugal equipment and so on.

Related Post: Palm Oil Pressing Machine>>

Palm Oil Refinery and Fractionation Plant Layout

1. Located At The End Of The Production Line

Considering that crude palm oil refining process and palm oil fractionation process are the final steps in palm oil production, placing these two areas at the end of the production line helps to facilitate the transportation of the final product from the mill to the warehouse.

Palm oil refining equipment includes oil-water separation equipment, deodorization equipment, bleaching equipment, etc. to improve the purity and quality of palm oil.

2. Consider Palm Oil Storage And Packaging Areas

Consideration is also given to palm oil storage and packaging areas, enabling finished products to be easily shipped out of the palm oil mill factory.

Related Post: Palm Oil Refining Plant>>; Palm Oil Fractionation Plant>>; Palm Oil Storage System>>

Small Palm Oil Refinery Plant For Sale

Commercial Palm Oil Fractionation Plant For Sale

Palm Oil Mill Waste Disposal Area Layout

1. Setting On The Edge Of The Plant

Design the waste treatment area at the edge of the factory, away from the main oil production area. Include waste treatment ponds, waste drying equipment, etc. to achieve environmentally friendly treatment of waste.

Palm oil mill effluent (POME) is the wastewater generated from palm oil processing activities which, due to its highly polluting nature, requires effective treatment before discharge into waterways.

Palm Oil Processing Equipment Maintenance Area Layout

1. Located In The Middle Of The Production Area

The equipment maintenance area should be designed in the center of the palm oil production line with a maintenance shop and spare parts store to ensure that equipment can be maintained and repaired in a timely manner.

2. Equipped With Monitoring System

The area should also include a monitoring system to detect equipment failures in advance and implement preventive maintenance.

Principles and Practices of Palm Oil Factory Layout Implementation

- Customized Layouts for Palm Oil Production: Small-Scale Centralized, Large-Scale Monolithic

When conducting small factory layout design for palm oil production, the production, auxiliary and living departments of the workshop can be centrally arranged in the same factory building. (of course, to ensure compliance with the building design fire code and health standard codes)

As for the factory with large production scale, there are significant differences in the production characteristics of each workshop, and the plant design needs to take a monolithic type. That is to say, the raw material processing, finished product packaging, production section, recycling section, control room and special equipment will be placed in a separate workshop.

- Single-Story Solution for Palm Oil Factory Buildings: Efficiency and Affordability

Palm oil factory building can be designed into single-story, multi-story or single-story and multi-story combination according to the needs of the process. The utilization rate of single-story plant is higher and the construction cost is lower. Therefore, in addition to the needs of process design, engineering design is generally used in single-story.

Plant can be set up in the multi-story steel operating platform to meet the requirements of the process equipment bit difference, the use of easy to move, disassembly, alteration of the steel operating platform instead of reinforced concrete operating platform or multi-story plant floor to adapt to the needs of the process changes.

- Optimal Factory floor plan: Rectangular Layout Design

Palm oil mill layout plan shape generally has rectangular, L-shaped, T-shaped and H-shaped. Rectangular plant is convenient for general layout, saving land, conducive to the arrangement of equipment, shorten the pipeline, easy to arrange the traffic outlet, there are more walls for natural lighting and ventilation.

The arrangement of different functional areas needs to be reasonable, such as raw material storage area, production workshop, equipment area, finished product warehousing area and so on.

Drawings and Information Necessary for Palm Oil Plant Setup

| Basis for factory layout design | Remarks | |

|---|---|---|

| Common design codes and regulations | Vegetable oil plant design specifications, leaching oil plant fire safety codes, equipment layout design engineering design regulations | |

|

Basic drawing materials

|

① Design task book | |

| ② Control point process flow diagram (construction drawings) | ||

| ③ Material accounting data and information on the nature of the material | Including the quantity and nature of raw materials, finished products, semi-finished products, by-products and wastes, and the quantity and treatment methods of three wastes | |

| ④ General layout plan of the plant and transportation routes | ||

| ⑤ Equipment calculation data | Including equipment diagram (outline dimensions) and connection position, height, operating conditions, equipment list, and power consumption | |

| ⑥ Workshop capacity list | ||

| ⑦ Consumption of public systems | Water supply and drainage, power supply, heating and refrigerated compressed air, and external pipe materials |