The palm oil industry plays a key role as one of the pillars of Indonesia's economy. For investors who want to build a factory in Indonesia, it is crucial to understand the mainstream processes of palm oil production and incorporate them into their plant construction business plan. This not only helps to improve productivity and product quality, but also ensures the success of the company in the local palm oil market and remains competitive.

Read More About Setting Up A Palm Oil Factory In Indonesia>>

Starting A Profitable Palm Oil Production Business in Indonesia

Therefore, this article will focus on introducing the mainstream local palm oil processing process in Indonesia to help those who aspire to set up a palm oil mill plant in this land to have a more comprehensive understanding of the industry, master the advanced technology and embrace the opportunities for future development.

ABC Machinery has experienced palm oil processing process design engineers and professional technicians, contact us to get stable support for your plant building business!

[3 steps Comprehensive Guide] Navigating the Palm Oil Production Process

Palm oil generally refers to the fats and oils extracted from the flesh of the palm fruit. The complete palm oil production process consists of three main parts: palm oil pressing, refining and fractionation. (Of course, you can contact ABC Machinery for customized unique process design for your palm oil mill business.)

Red Palm Oil Production Process Flow Diagram

Crude Palm Oil (CPO) Refinery Process Steps

Red Palm Oil Extraction Process

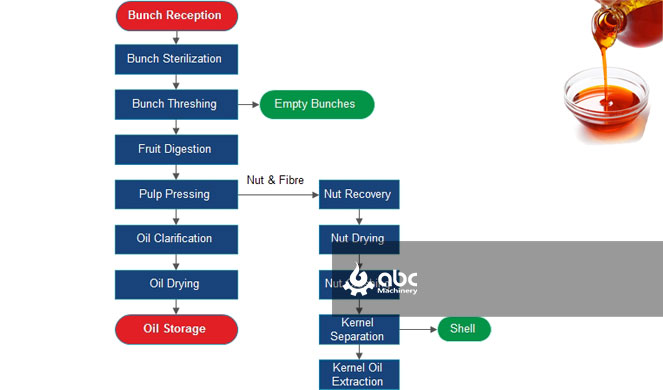

Oil palm fruit bunches → Sterilizing → Threshing → Digesting → Screw/Hydraulic pressing → Filtration → Crude palm oil

- Sterilizing Process: Fresh palm fruit bunches received from the plantations are steam-fermented at high temperatures to destroy the lipase enzyme in the pulp to facilitate fruit removal.

- Threshing Process: Palm fruits are separated from the bunches using a thresher. There are two common types of threshers: simple type threshing machine and drum type threshing machine. Manual de-fruiting is also an option.

- Digesting Process: The palm fruits are mashed into a paste. The mashing process destroys the cellular structure of the palm fruits and improves the efficiency of palm oil extraction.

- Pressing Process: Pressing is a key part of palm oil making. This step requires strict temperature and pressure control. As a palm oil production equipment manufacturer, ABC Machinery can provide you with single screw palm oil press machine and double screw palm oil press machine.

- Filtration Process: Residual impurities and solid particles are removed through different levels of filtration equipment to further improve the purity of the oil.

Palm Oil Refining Process

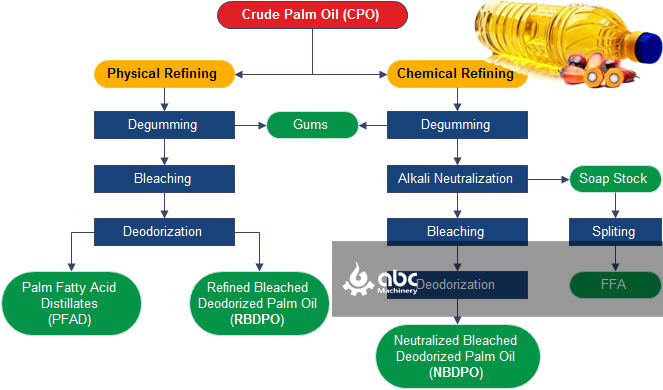

Crude palm oil → Degumming → Deacidification → Decolorization → Deodorization → Refined palm oil

- Degumming Process: removing some of the waxes, impurities, and pigments that may be present in gross palm oil. This step usually involves freezing or heating to solidify or dissolve the impurities, which are then separated by methods such as filtration or centrifugation.

- Deacidification Process: Reducing the free fatty acid content of palm oil. This is usually done by alkaline treatment or steam deacidification.

- Decolorization Process: Decolorization is the process of removing the pigments from hairy palm oil to make it more transparent in color. This step usually involves activated clay or other adsorption to adsorb the pigment particles.

- Deodorization Process: Removal of off-flavors and undesirable odors from the oil by steam deodorization or other techniques helps to enhance the flavor of palm oil.

RBD Palm Oil Products (After Refinement, Bleaching and Deodorization Process)

Palm Oil Fractionation Process

Refined Palm Oil → Heating Section → Crystallization Section → Filtration Section → Palm Soft Fat + Palm Stearin

After refining palm oil, crystals will precipitate at low temperatures, so fractionation may be an option for the stability of the oil in storage or for different applications.

- Heating Section: In this stage, the oil is heated to a certain temperature in order to keep some of its components in a liquid state, thus making it easier to proceed to the next stage of the process.

- Crystallization: By controlling the temperature, specific components of the oil are crystallized to form crystals. These crystals include the main components of palm stearin, while the unsaturated fatty acids remain in the liquid state

- Filtration Section: After crystallization, the palm oil is passed through a filtration section where the crystals formed are separated from the liquid oil. This process is designed to remove excess crystals, impurities and other unwanted substances.

- Separation Of Palm Olein And Stearin: After the above process steps, the product obtained consists of palm olein and palm stearin. These two have different melting points and uses. Palm soft fat is mainly used for food processing and making food oils, while palm stearin is commonly used in the production of industrial products such as foodstuffs, cosmetics and soaps.

Are you interested in building a palm oil processing plant in Indonesia? Our professional team is ready to provide you with professional consulting services on palm oil processing technology. Please click the button below and let's start a successful cooperation journey together!

Optimizing Palm Oil Production: Key Operation Points in the Manufacturing Process加数据

- Preventing Palm Oil Rancidity: Steam Treatment to Inhibit Fermentation and Enzymatic Activity.

Palm fresh fruit, with high moisture content and susceptibility to rancidity, undergoes a crucial steam treatment process lasting approximately 30 minutes. This step is essential to kill fermentation and inhibit enzymatic activity, ensuring the quality of palm oil.

- Specialized Equipment and Techniques for Efficient Pressing Without Kernel Breakage

The oil palm fruits after mechanical mashing are pressed to make palm oil, you can use three kinds of oil extraction equipment: special double screw oil press, hydraulic oil press and basket centrifugal separator. The main characteristics require specialized pressing of the oil from the palm flesh without breaking the palm kernel.

- Achieving Quality Excellence via Centrifugal Dewatering and Refinement Processes

Crude palm oil, known for its initially high moisture content, undergoes a dewatering process through centrifugal separation, resulting in an impressive 80% reduction in moisture content. Subsequent refinement further reduces acidity levels, producing a high-quality palm oil ready for various applications in the food industry.

Characterization and Innovations of Palm Oil Processing in Indonesia

Coexistence of Tradition and Innovation in Palm Oil Processing

Currently, the dominant palm oil production processes in Indonesia are modern, and these large mills typically employ continuous sterilization, threshing, and pressing processes to extract oil from the palm fruit bunches (As noted earlier).

Traditional palm oil processing methods in Indonesia have a long history, including manual extraction using simple tools. These traditional methods are still prevalent in some small-scale and remote areas, but tend to be inefficient and labor-intensive.

Green Palm Oil Processing Technology Innovation for Sustainable Development

The palm oil industry in Indonesia has faced criticism for its environmental impact, leading to explore green technologies to minimize impact of palm oil production. This includes innovations in water recycling, energy efficiency, and emissions reduction. The implementation of traceability systems and certification standards (e.g., RSPO - Roundtable on Sustainable Palm Oil) ensures that palm oil products meet environmental and social sustainability criteria.