ABC Machinery can offer turnkey palm oil extraction projects. Feel free to send an inquiry for more details! We will be always at your service!

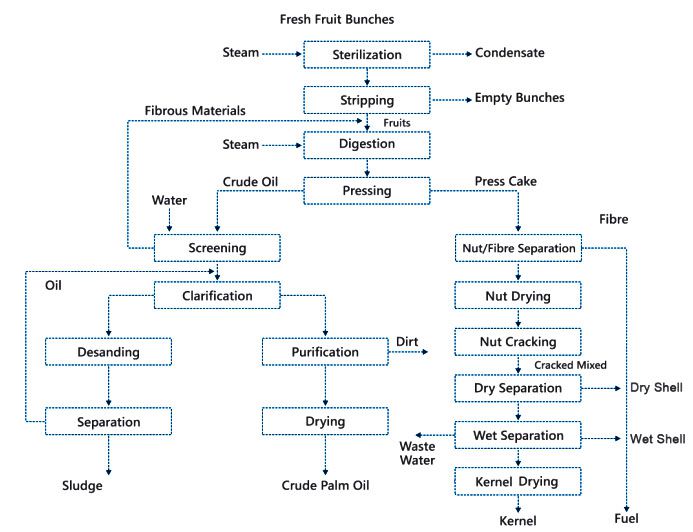

Typical palm oil extraction process: fresh fruit bunches (FFBs) reception, sterilizing, fruit bunches threshing, fruit digesting and oil extraction. The crush palm oil is generally further processed in palm oil refinery plant to manufacture edible oil.

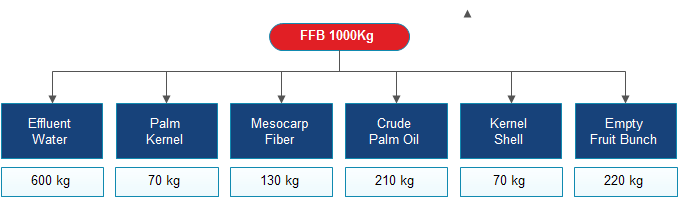

Extraction of per Ton Fresh Fruit Bunch

Fruit Reception – The First Step of Palm Oil Extraction

The palm fruits are as bunches when arriving the fruit reception/receiving station of palm oil extraction plant. Before the processing of oil extraction, they are weighed in trucks by use of weighbridges. It should be underlined here that the quality of final palm oil is initially affected by the quality of bunches arriving at the palm oil mill. The palm oil extraction process or machine can only prevent or minimize the further deterioration, but cannot enhance this quality.

| Weighbridges | FFBs Unloading | Fruit Bunches Reception |

| Sterilizer Cage | Reception Station of Palm Oil Extraction | Palm Oil Mill Sterilizing Section |

Effect Factors of Final Palm Oil Quality and Composition

The field calculates that influence the structure and last nature of palm oil:

- Oil Palm Tree Species

- Oil Palm Tree Age

- Agronomic

- Natural

- Gathering Technique

- Handling And Transport

Maybe some measures can be took during harvesting and transporting. However, most of the above factors are beyond control, especially in scale-scale palm oil extraction plant. The following is the complete process flow of large palm oil mill. Feel free to inquire about the cost, if you are interested our palm oil extraction machine or plant. (E-mail: info@palmoilmillplant.com)

Process of Scale-scale Palm Oil Extraction Plant

Technique of Palm Fruit Harvesting

The oil content of the palm fruit is very low in the early phases of formation and it increases as the fruit grow. When the fruits is maturity, the oil content is about 50% of mesocarp weigh.

The fresh fruits apt to be bruised in many cases before extraction of palm oil, especially during the processes of harvesting, loading and unloading. However, the FFA (free fatty acids) in the bruised part of fruit can increase to 60% rapidly in just an hour, which greatly affects the composition and quality of final palm oil. The answer to reduce the damage to palm oil extraction quality is to send the fresh fruit bunches to process and extracting the fruits as early as possible once harvested, at the latest within 48 hours.

About Oil Palm

Oil palm is mainly distributed in countries with high rainfall in tropical climates, such as Malaysia and Nigeria. Due to its economic importance as a high-yielding wellspring of edible and specialized oil, oil palm is now grown as plantation crop.

Oil palm is mainly distributed in countries with high rainfall in tropical climates, such as Malaysia and Nigeria. Due to its economic importance as a high-yielding wellspring of edible and specialized oil, oil palm is now grown as plantation crop.

The palm bears its fruit in bunches varying in weight from 10 to 40 kg. The individual fruit, ranging from 6 to 20 gm. The fruit is comprised of exocarp (outer skin), mesocarp (pulp) and central nut. The central nut consists of shell (endocarp) and kernel. The palm oil is extracted from the fibrous matrix of palm pulp, while palm kernel oil is extracted from the kernel.