Screw oil pressing plant is suitable for both small and large palm kernel oil extraction plant. Screw oil pressing is a kind of mechanical oil extraction process which mainly includes:

Screw-Pressing Section

Oil Clarification Section

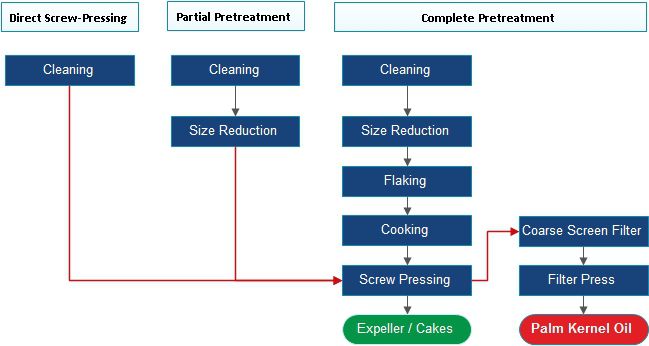

The following the three different processes of palm kernle oil extraction plant.

Mechanical Palm Kernel Oil Extraction Methods

There are three variations of mechanical kernel oil extracting procedure: direct screw pressing, partial pretreatment and complete pretreatment.

- Direct screw-pressing: Some small palm kernel oil mills is designed without any pre-treatment machines. The kernel is fed directly into the oil presses, crushed and compressed at the same time in the oil pressing machine. Double pressing is suggested to achieve higher oil extraction rate. Direct screw-pressing is suitable for small scale oil mill with capacity less than 10 tonnes per day.

- Partial pre-treatment: The kernels are crushed to small fragments before oil expelling. Cooking is also carried out in some cases.

- Complete pre-treatment: The full pre-treatment processes including cleaning, crushing, flaking and cooking are carried out before oil pressing. Large oil mill plant with capacities between 50 ~ 500 tonnes per day choose this kind of kernel oil processing procedure. Palm kernel oil combined with fresh palm oil mill plant adopts complete pretreatment procedure.

Palm Kernel Oil Mill Plant Design

Kernel Pre-treatment Section

The pretreatment section greatly affect the oil extraction efficiency and production cost. Before feeding into oil expeller (oil press), the palm kernels must be cleaning to remove impurities, otherwise they may damage the expeller, increase maintenance costs and reduce the quality of final oil product.

| Crusher | Flaker | Cooker |

- Magnetic separator is used to remove metal debris;

- Vibrating screen is used to remove stones and sand;

- Break roller or winging hammer grinder is used to break the palm kernels into small pieces.

- Flaking machine is used to pressing the kernel fragments into flakes (0.25 to 0.4 mm thick).

- Cooker is used to adjust the moisture content of the palm kernel flakers to optimum level through steam conditioning. Besides, cooking process can also help reducing viscosity of oil, rupturing cell walls, coagulating the protein and facilitating separation of oil from protein materials. In the palm kernel oil pressing process, the meals are generally cooked to a moisture content of 3 % at 104-110°C.

Screw-pressing Section

Oil expeller or screw press is the standard oil processing machine in the modern oil milling industry worldwide.

| Small Oil Press | Multi-function Oil Press | Large Oil Pressing Machine |

After properly pretreatment, the meal is then fed into palm kernel oil press (screw press), which is mainly composed of a revolving worm and a stationary perforated cylinder called barrel or cage. With the worm revolving, the meal is forced through the cage. The volume axially displaced by the worm diminishes from the feeding end to the discharge end, thus compressing the meal as it passes through the barrel. While the palm kernel expeller or cake is discharged from an annular orifice, the expelled oil will flow out from the barrel of screw oil press. For cold oil pressing process, a circulating water system is added to cool the worm-shaft and manufacturer high quality cold pressing oil product.

Oil Clarification Section

The expelled oil discharged from the palm kernel oil press is then drained to a reservoir. The crude palm kernel oil inevitably contains unwanted impurities and foots, which must be removed to produce clear oil prior to storage.

| Small Oil Filtering Machine | Large Plate Frame Oil Filter | Vacuum Leaf Oil Filter |

- Revolving coarse screen or decanter is used to remove large solid impurities;

- Filter press is used to remove the remaining solids and fines;