Palm oil production process involves the use of large quantities of water and chemicals, so palm oil mill effluent (POME) can contain a variety of hazardous substances that pose a potential threat to water bodies and ecosystems. With the growing global awareness of sustainability, investors in the palm oil mill industry are facing stricter environmental requirements.

Starting A Profitable Palm Oil Mill Business in Indonesia

This paper aims to provide important information and practical advice on wastewater treatment for investors who are planning to start a palm oil mill plant in Indonesia. By properly treating and managing effluent, the foundation for long-term business success is laid.

Unraveling the Processing Steps Leading to Palm Oil Mill Effluent (POME)

Wastewater from palm oil mills mainly comes from the cleaning process of oil palm fruits, palm oil pressing/solvent extraction process and refining process. These effluents usually contain suspended solids, oils and fats, organic and inorganic substances, and other pollutants from the different process steps, which can be hazardous to water bodies and soil.

Understanding the sources of palm oil mill effluent helps us to take our countermeasures to minimize wastewater generation, and reduce treatment and management costs.

- Effluent From Palm Oil Leaching Extraction Process

If your palm oil mill adopts solvent extraction method to extract oil, you need to pay attention to this point. The generation of wastewater from the leaching section is mainly due to solvent recovery system. The solvent vapors evaporated from the crude oil and cake meal are converted to liquid solvent through a condenser. After the liquid solvent water is separated, the resulting wastewater is fed into a water separation tank. In the water separation tank, the water is separated to obtain clean water and effluent.

Small and Large Scale Palm Oil Solvent Extraction Machines For Sale

- Effluent From Crude Palm Oil Refinery Process

Wastewater generated from palm oil refining process mainly comes from hydration degumming workshop and deacidification workshop.

► Effluent from hydration and degumming stage of refining process. The crude phospholipids separated from the palm oil refining section contain a large amount of water, which needs to be dehydrated by the concentrator, and after concentration, the evaporated water is condensed and discharged as effluent.

In addition, the centrifuge needs to be flushed with water, resulting in flushing effluent. The main pollutants are phospholipids and oil.

► Effluent from Deacidification stage of refining process. After alkali refining of hydrated oil, the centrifuge separates alkali refining oil and soap foot, and rinses with water, and rinsing wastewater is discharged intermittently.

After separating the soap foot, the hydrated oil needs to be washed twice with water, and then the oil and water are separated by centrifuge. The separated effluent is discharged after further oil recovery.

There are two processes for palm oil refining, physical refining and chemical refining, which produce different pollution loads. Compared to physical refining, chemical refining process generates serious effluent pollution, but its by-products have higher economic value.

Related Post: Palm Oil Physical Refining Plant & Chemical Refinery Plant>>

| Comparison Of Emissions from Physical and Chemical Refining Process | ||||

| Refining Method | Displacement Per Ton Of Oil /(m³/t) | COD/(kg/t) | BOD/(kg/t) | Oil/(kg/t) |

|---|---|---|---|---|

| Physical Refinement | 0.48 | 0.85 | 0.41 | 0.2 |

| Chemical Refining | 0.72 | 4.17 | 1.36 | 1.0 |

From Source to Solution: Understanding Palm Oil Mill Effluent Treatment Process

For those wishing to setup a palm oil mill factory in Indonesia, it is vital to understand the importance of effectively treating and managing POME to ensure the long-term stability of their processing plant operations.

Regarding the treatment technology of oily industrial effluent, it is summarized as the removal of a large amount of oil in the water while taking into account the removal of organic matter, suspended solids, soaps, acids and alkalis, sulfides and so on. So, palm oil processing effluent treatment means for the physical method of separation, chemical removal, biological degradation.

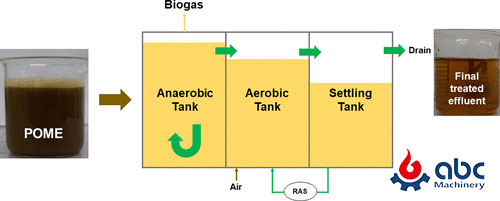

One Integrated Anaerobic–Aerobic Process Treating POME

Plam Oil Mill Plant Effluent Conventional Treatment Process (One Example)

Inlet water → Grating - Grease trap → Regulating tank → Air flotation tank → Biological treatment → Depth treatment → Effluent water

During the process of palm fruit digesting and palm oil pressing, a large amount of organic palm wastewater (POME) will be discharged, and the general COD concentration is above 50,000 mg/L.

- Air Flotation Process in Wastewater Treatment

Remove suspended emulsified oil and grease in water by air flotation method, while combining with biological method, it can make the oil content in water drop to 10-20mg/L, and the organic matter reaches the level of permissible release.

- Anaerobic Contact Process

Adopting anaerobic contact process to treat palm oil effluent, the average BOD concentration of wastewater in the palm oil production period is 30,000mg/L, after anaerobic treatment, the BOD removal rate reaches 99%, and the effluent is directly discharged into the water body.

ABC Machinery’s team of experts is ready to assist you in implementing state-of-the-art effluent treatment solutions for your palm oil mill in Indonesia. Contact our experts today to discuss a customized strategy for your palm oil mill and turn challenges into opportunities for a greener tomorrow!

Sustainable Solutions: Leading Resource Recovery from Palm Oil Mill Effluent in Indonesia

Currently, palm oil effluent in Indonesia, the highest palm oil producing country, is currently disposed of mainly by simpler methods such as oxidation ponds, which emit about 1.35 million tons of carbon dioxide per year as greenhouse gas carbon emissions. This not only brings environmental hazards to the local area, but also has a bad impact on the regional and even global environment.

At present, the use of POME to produce biogas, fertilize, protein, energy, and other resource utilization technology has matured, which can not only eliminate the environmental pollution caused by POME treatment, but also alleviate the problem of insufficient supply of electrical energy and protein resources for remote palm mills, which can help palm oil mills achieve a win-win situation for both the environment and economic value. Investors should pay attention to this.