Recently, a complete production project including palm oil milling plant, palm kernel oil pressing plant and final palm kernel oil refining plant have been setup in Nigeria, which is ordered by our customer last year. At that time, we sent our engineers and technicians to Nigeria to conduct the installation, debugging and operation traning etc. Here are the details about these palm oil production and palm kernel oil pressing line. (Related article: how to start palm oil business in nigeria>>)

| Project Name | Palm oil milling and palm kernel oil pressing and refining plant |

|---|---|

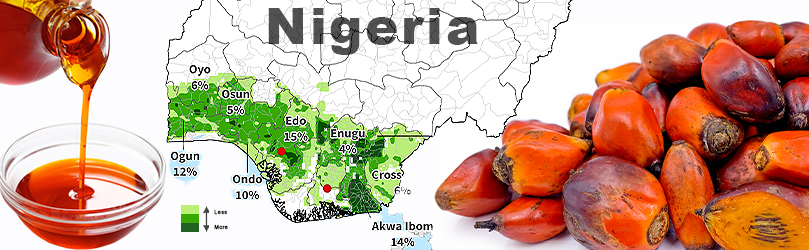

| Project Location | Nigeria |

| Production Process | 1TPH Palm oil milling plant, 10TPD Palm kernel oil pressing plant, 3TPD palm oil refinery plant |

| Raw materials | Fresh palm fruits, palm kernel |

Complete Palm Oil and Palm Kernel Oil Production Plant Setup Display

Based on the requirements and actual condition of our customers, we have designed and developed a comprehensive solution. We have carefully designed a palm fruit palm oil production plant, as well as a separate palm kernel oil pressing plant. Additionally, to ensure the highest quality of palm kernel oil, we have also developed a state-of-the-art palm kernel oil refining plant. (Related article: palm oil processing machine price in nigeria>>)

Palm Oil Processing Plant Display

Palm fruit oil production process design: fermentation, dehulling, mashing, oil extraction, vibratory sieving, settling, filtration, drying.

If you have interests in building palm oil making line, you can contact us for help!

Palm Kernel Oil Pressing Machinery Setup Site

Palm kernel oil production process deisgn: steaming, shelling, crushing, pressing, frying, blending, oil extraction, filtration. (Related article: how to make palm kernel oil>>)

Palm Kerne Oil Refining Line Display

Palm kernel oil refinery plant process flow design: heating, refining, decolorizing, filtration, deodorizing. (Related article: palm oil refinery plant cost >>)

For more details about palm oil making mchine price and factory building cost, you can contact us now!

How Much Does It to Start a Palm Oil Milling Business in Nigeria?

Are you considering venturing into the palm oil industry in Nigeria? Maybe one of the first questions that come to mind is, "How much does it cost to set up a palm oil plant?" Here is the factors need to consider when you start a palm oil milling busness, this writer wish it can help you. (Read more: palm oil business plan in nigeria>>)

Starting a Profitable Palm Oil Business in Nigeria with Low Cost

- Land Acquisition and Site Development Cost

The first significant expense in setting up a palm oil plant is land acquisition. The cost varies depending on the location, size of the land, and proximity to transportation networks. Additionally, site development expenses, such as clearing, leveling, and infrastructure development, should be taken into account. These initial investments are crucial for creating a solid foundation for your palm oil plant. (Learn more: palm oil mill plant layout>>)

- Palm Oil Milling Equipment Price

Investing in high-quality machinery and equipment is essential for efficient palm oil production. The cost of equipment depends on the scale of your plant and the level of automation you wish to incorporate. It is crucial to choose reputable suppliers and consider the long-term reliability and maintenance costs associated with the machinery. To ensure the production of high-quality palm oil, you will need processing and refining facilities. The cost of these facilities depends on the capacity and sophistication desired. (Read more: palm oil processing plant>>)

For the latest price list of palm oil milling machinery, please contact us now!

- Labor and Training Cost

Skilled labor is vital for the successful operation of a palm oil plant. The cost of labor will depend on factors such as the size of the plant and the level of automation. Additionally, investing in employee training programs ensures a knowledgeable and competent workforce, enhancing productivity and product quality. (Learn more: how much does it cost to build a refinery plant>>)

- Utilities and Infrastructure

Proper provision of utilities such as water, electricity, and waste management is essential for smooth plant operations. Costs associated with utility connections, generators, waste treatment systems, and infrastructure development should be considered during the planning phase.

- Regulatory Compliance and Certifications

Complying with relevant regulations and obtaining necessary certifications, such as quality and sustainability certifications, is an important aspect of setting up a palm oil plant. Budgeting for these compliance costs is crucial to ensure a smooth and legally compliant operation.