ABC Machinery has strong resources in palm kernel oil refining. We can provide mini or small palm kernel oil refinery equipment for home or small edible oil refining plant use. At the same time, we are also an expert in supplying turnkey projects of large palm kernel oil refining. The refining capacity ranges from 1 TPD to 400 TPD.

How Crude Palm Kernel Oil is Refined?

- Alkali Neutralization

Adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.

- Static Precipitation

Slowly stir up the oil to rise the temperature to 50 ~ 52 ℃ for 40 minutes, then continue to stir it for 10 minutes until the the separation of the oil soap, and then stop stirring and close the indirect steam. Let the oil motionless for about 6 hours. After that it is time to separate the oil soap.

- Washing

Rise the temperature of the oil that is separated from the oil soap to 85 ℃ under the stirring. Then, add the aline-alkaline water that is at the temperature of 90 ℃ and the amount is about 15% of the oil. The aline-alkaline water contains 04% of caustic soda nd 0.4% of industrial salt. When the adding of the aline-alkaline water is finished, stop stirring and the lower waste water can be discharged after 30 min standing. After wastewater is discharged, the oil temperature still at 35 ℃. Then inject 15% of the boiling water (water) into the oil once again. When the water is added over, stop stirring. The lower waste water will be discharged after 5 hours standing. Such water washing process should be completed about 2 to 3 times.

- Pre-decoloring

Start the vacuum pump to suction the cleaned oil after alkali refining into decoloring pot, heat up to 90 ℃, dry and dehydrate for 30 minutes at a vacuum of 99 kPa. Then, absorb a small amount of acidic clay and stir for 20 minutes. After decoloring technique, cool the to 70 ℃ under vacuum condition. Then take all the oil into filter press by gear pump for oil filtration.

- Decoloring

Get oil after pre-coloring refining into the decoloring pot, rise the oil temperature to 90℃ at a vacuum of 99 kPa (more than 740 mm Hg). Then, inhale 100 kg of acid clay, 60 kg of activated clay (take 6 tons of oil as example), and stir continuously for 10 minutes. After decoloring, cool the oil to 70 ℃ under vacuum condition and take the oil into the press filter for next filtering.

- Deodorization

Start the vacuum pump to suck the decolorized oil into the deodoring pot. When indirect steam to heat the oil to 90 ~ 100 ℃, began to gush steam directly, and oil temperature rise to 185 ℃, begin to vacuumize with steam jet pump, maintain the residual pressure in 400 ~ 666 Pa, he oil temperature is still 185 ℃, continue to deodor for about 5 hours. Cool the oil to 30℃ at vacuum condition and filter it to quickly get the refined palm kernel oil.

Through oil refining process, the moisture, impurities, acid value, peroxide value and other index in the palm kernel oil can reach the quality standard. And refined palm kernel oil is not easy to rancidity and deterioration, and can be stored for longer time. The color of refined palm kernel oil is bright and nice, the taste is good, and there are no a lot of lampblack when cooking. (You may also like Palm Kernel Oil Expeller Machine >>)

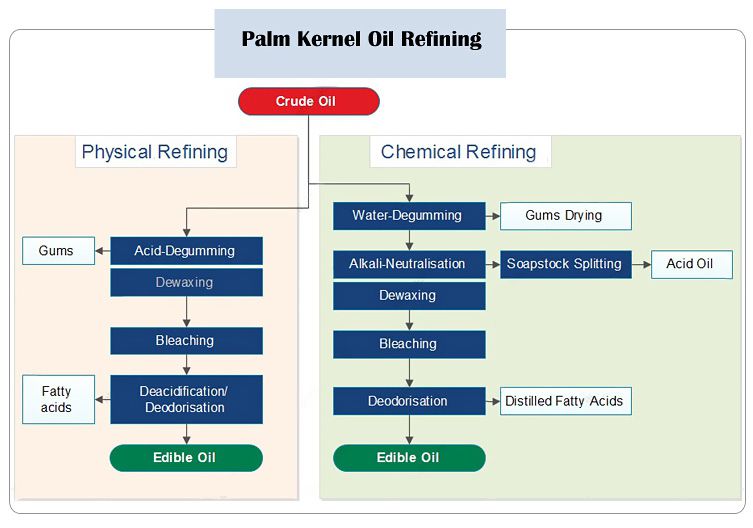

Main Palm Kernel Oil Refining Methods

The main content of palm kernel oil is glyceride. But just like other oils and fats, it also contains part of nonglyceride components. And the nonglyceride can be divided into two main parts: non oil-soluble impurities and oil-soluble impurities. The non oil-soluble impurities mainly refer to fiber, shell and free moisture. And, the oil-soluble impurities are free fatty acid, phospholipid, microelement, carotinoid, oxide, tocopherol and more. The refining process is to remove these impurities and maintain more beneficial components, further turn the crude palm kernel oil into qualified edible oil. The main oil refining method for crude palm kernel oil is as follows.

Large Scale Palm Kernel Oil Refinery Plant

-

Mechanical Oil Refining Method

-

Chemical Oil Refining Method

-

Physical and Chemical Oil Refining Method

This method mainly include hydration, decolorization, steam distillation, etc., hydration mainly removes phospholipids; decolorization mainly removes pigments, and steam distillation is used to remove odorous substances and free fatty acids.Detailed process of this method is Crude pko, degumming, neutralization, washing, drying, filtration, pretreatment oil storage tank, deodorization, fractionation, cooling and storage. (Read more about Palm Oil Physical and Chemical Refining Process >>)

Crude Palm Kernel Oil Refining Process

- Hello, I am interested in buying Mini Palm Kernel Oil Pressing Line and Mini Palm Kernel Oil Refining Line, Can you kindly give me all necessary information, including cost.

- Thanks for your inquiry. Please let me know what is the capacity do you need of the small oil pressing line? How many raw materials do you want to process in one hour? How about local 3phases electricity?--V?--Hz? So, we can design and quote you accordingly.

- I wish to request a quotation for 20 M/T capacity per day. A refinery that would refine palm kernel oil into vegetable/edible oil. We are already into palm kernel crushing and we do have expellers / filter press machines. we want to add value to what we produce (palm kernel oil) by further refining the oil into vegetable/edible oil.

- The standard 20TPD oil refinery plant quotation has send to your email for your reference. Pls check it.