What is the cost of setting up a small palm kernel oil production line? Actually, there are many aspects should be taken into consideration when setting up a palm kernel oil production plant, including the capacity, the quality of final produced palm kernel oil, the palm kernel oil processing technology and more. So, the exact cost of setting up the palm kernel oil production line would be different based on the specific requirements and conditions.

<< Palm Kernel Oil Production Business Plan

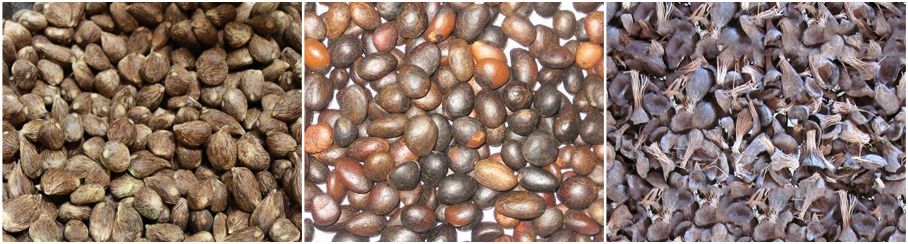

Palm Kernel and Shell

Palm Kernel Oil Production Line

Palm kernel oil is totally different from palm oil, although they are both obtained from oil palm. Therefore, the palm oil extraction and palm kernel oil production different in the technology, process, equipment and more. The production process of palm kernel oil: Separation of Kernel and Shell → Crushing → Steaming → Pressing → Oil Clarification → Crude Palm Kernel Oil. Below is the detailed process of palm kernel oil production. (Latest Post: Palm Oil Processing Plant Cost >>)

Small Palm Kernel Oil Production Line

- Kernel Shell Separation

The kernels of palm can be obtained by crushing the kernels. Palm cores can always be used as fuel in boiler rooms. Shelling can speed up the oil yield, improve the quality of crude oil and cake, protect palm kernel oil equipment from wear and tear, and increase the reasonable production of equipment.

- Crushing

Palm kernels after shelling are larger. If it is used for oil extraction directly, the machine will be damaged greatly. The oil yield rate is also be reduced. Usually we need to crush the palm kernels to meet the requirements of the palm kernel oil pressing process. Crushing equipment is mainly gear roll crusher.

- Steaming

The purpose of steaming is to destroy oil cells by temperature and water, denaturing protein, gathering oil, reducing oil viscosity and surface tension, adjusting elasticity and plasticity of billets, and passivating enzymes. Steaming and frying equipment in palm kernel oil production line is mainly steaming and frying pan.

- Pressing

With the help of mechanical external force, the method of extracting oil from palm kernel by extrusion. Palm kernel oil press is mainly divided into two types: special palm kernel oil press and conventional oil press. (Related Product: Palm Kernel Oil Expeller >>)

- Oil Clarification

Purer crude palm kernel oil can be obtained by separating impurities from oil through palm kernel oil filter.

- Crude Palm Kernel Oil

The quality of palm kernel oil obtained through the above steps has reached the standard of direct consumption. If you have special requirements, special uses, you can send palm kernel oil to the palm kernel oil refinery plant for further processing. (Related Artice: Palm Kernel Oil Refining Process >>)

Main Technical Data of Palm Kernel Oil Production Line

| Parameter | Technical Data |

|---|---|

| Capcity | 1~1000 Ton/day |

| Oil Yiled of Palm Kernels | > 45% |

| Residual Oil of Cake | about 6% |

| Main Equipment | sheller, crusher, steam frying pan, palm kernel oil press, oil filter and so on. |

How to Choose the Palm Kernel Oil Production Equipment?

When facing the various model of palm oil processing equipment, many customers will lost and have no idea about how to choose suitable equipment for palm kernel oil production. As the core palm kernel oil produciton, palm kernel oil press is very important. What's the difference between a professional palm kernel oil press and a conventional oil press? Can it be used in general?

Generally speaking, there are professional palm oil press for palm fruit, professional palm kernel oil press and conventional oil press for oil-bearing seeds. In theory, what kind of oil should be treated with the corresponding oil press equipment, but in the process of communication with customers, many customers still have such questions: I have a conventional oil press, but I want to deal with palm kernels with a conventional oil press? Can it possible? Here will give you a brief explanation.

Palm kernel oil press and conventional oil press can be used in general. The difference between conventional oil press and professional palm kernel oil press is mainly reflected in the following aspects:

- Special Palm Kernel Oil Press Features

- Convential Palm Kernel Oil Press Features

Through the above comparison, I believe you have a general understanding of conventional oil press and palm kernels special oil press. You can determine which one you should buy according to their own actual situation, if your main oil is palm kernels, you do not intend to deal with other conventional oils, while your processing capacity is relatively small, you are advised to buy conventional oil press; If your production is relatively large, you are advised to buy palm kernels zh oil press; If your main oil is palm kernels, you also beat. To deal with other conventional oils, you are advised to buy conventional oil press. Any questions, please contact us directly!