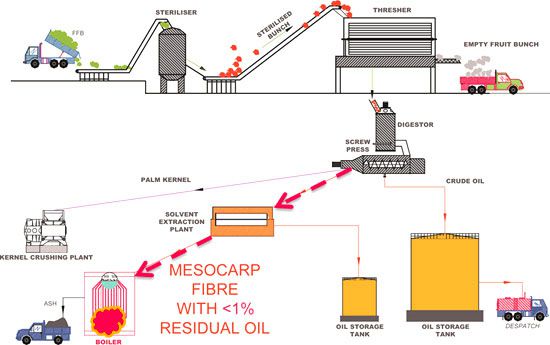

Before making your business plan for starting a palm oil extraction factory, it is important to learn about the palm oil mill process. The process of palm oil extraction is very different from the processing of other seeds. Gnerally, palm oil mill includes 6 processes: fruits reciving, cooking/sterilizing, threshing, digesting, oil pressing, crude oil clarification, refining and fractionation, and pal kernel recovery.

Palm Oil Mill Process Machines

ABC Machinery is a top-rated palm oil machine manufacturer and supplier in China, with rich experience in setting up both small and large palm oil extraction plant. Our palm oil mill process design is low cost and energy-saving. We have successful palm oil milling factory project in Nigeria and other Countries. We can ensure the first-class service with the best palm oil mill process machine price. Welcome get in touch with us to get a customized project plan for starting your own palm oil company in Nigeria or other places. We can quote the latest cost of establishing a palm oil extraction mill.

Market of Palm Oil Extraction

Smal Palm Oil Process Design for 1-5 ton/h Factory

Innovative work in numerous controls - organic chemistry, synthetic and mechanical building - and the foundation of estates, which gave the chance to expansive scale completely motorized handling, brought about the development of an arrangement of preparing steps intended to extricate, from a gathered oil palm group, a high return of a result of worthy quality for the global eatable oil exchange. The oil winning procedure, in outline, includes the gathering of crisp natural product clusters from the estates, cleaning and sifting of the bundles to free the palm organic product, squashing the foods grown from the ground out the unrefined palm oil. The raw petroleum is additionally treated to clean and dry it for capacity and fare.

Palm Oil Mill Process

Palm oil is extracted from the fruits of the oil palm tree, which is developed in tropical districts of Asia and Africa. While palm oil makers depend on various methods to extracte this oil, the fundamental advances engaged with palm oil creation continue as before. Manufacturers must plant a supply of oil palms, and direct their consideration through development. The fruits of the tree would then be able to be reaped and prepared to discharge the oil. The last advance in palm oil generation includes refining the oil to meet the requests of different clients. The greater part of worldwide palm oil creation happens everywhere manors in Malaysia and Indonesia. Makers in these nations develop huge oil palm crops, which flourish in the tropical conditions found in this piece of the world. When the fruits of oil palm have developed, groups cut them off the trees in substantial clusters utilizing cleavers or different instruments.

Mechanical Extraction of Palm Oil

The natural palm fruits are gathered, regularly by hand, and exchanged to handling destinations found locally and abroad. Amid this time, it is basic to deal with the palm fruits with consideration to limit wounding, which can contrarily affect oil creation.First,the palm natural frtuis experience a procedure known as sterilizing.This process should be possible by either cookinglsmoking which is done subsequent to sifting process or by steaminglbubbling which ought to be done before sifting process.

Next, the palm fruits experience a procedure known as sifting, in which the fruits are isolated from whatever remains of the cluster. Vast palm oil process plant put the palm fruits in turning drums to finish this procedure, while little palm oil creation offices perform sifting by hand.

Subsequent to sifting, the following stage in palm oil creation includes oil squeezing or pressing the palm fruits to isolate the oil from the skin and mash. A few offices put the organic product into substantial turning drums, which begin to separate the foods grown from the ground a portion of the oil. This is trailed by squeezing, wherein substantial metal plates are mechanically squeezed into the organic product to press out the oil. Palm oil press machines may utilize water powered or pneumatic capacity to process expansive bunches on the double. The oil is then weakened with water and separated through a screen to help expel garbage and polluting influences.

At this stage, the crude palm oil can be sold directly or sent on for further palm oil refining and fractionation (Read more about Palm Oil Fractionation Machinery and Palm Oil Refining Machinery) . For further handling of palm oil,the palm oil refining procedure and palm oil fractionation process is necessary.The palm oil refining procedure can dispose of the destructive polluting influences and unnecessary substance in the unrefined consumable oil, getting standard palatable oil by using the physical techniques and compound procedures.

Amid fractionation, palm oil is warmed to isolates out the different triglycerides contained inside. This isolates low-quality oil from higher quality oils, which are wealthy in fundamental unsaturated fats yet contain less soaked fat than unpurified palm oil.