ABC Machinery has won great reputation in the field of palm oil milling machine and palm oil mill plant. With professional design and development team, all the product provided by ABC Machinery is labeled high quality and efficiency. What’s more, the price and construction cost of a palm oil production plant is minimized by utilizing ABC Machinery’s machinery and production lines.

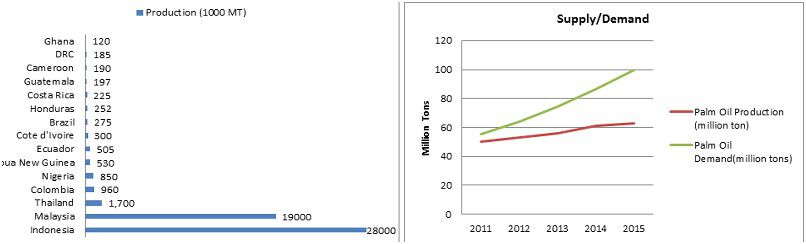

Rapid growing demand of palm oil

The increasing demand of palm oil brings great opportunities to palm oil production industry. Palm oil suppliers and palm oil mill machinery manufacturers are responding actively to the growing demand. It’s estimated that global demand of palm oil will double in the next five years, increasing from 5.3 million tonnes in 2014 to 11 million by 2020. World largest palm oil suppliers and palm oil milling machine manufacturers have already adopted new processing machinery and sourcing requirements.

Complete stages of palm oil products

Stage one - Nursery

before being transferred to the plantation fields, germinated seeds of oil palm are planted.

Stage two - Plantation

Every hectare of land can plant about 140 oil palms. After about three years, the palm fruits are harvested for use. Between 7th to 18th years, the production of palm fruit will reach the peak. And the yield will drop thereafter.

Stage three - milling

Palm oil milling mainly refers to palm oil sterilizing and palm oil threshing. They are professional palm oil milling machines in the mill plant to maximize the output of palm oi. The palm fruit is sterilized for palm oil - from the fresh fruit and palm kernel

Stage four - processing

Crud palm oil is refined with palm oil refinery machines and is separated into different forms of oil . And palm kernels are extracted for palm kernel oil

Stage five - Manufacturing

Final palm oil is used for cooking or making food, such as ice cream, chocolates and more.

It also can be used for making biodiesel. While, palm kernel oil is used in shampoos, soaps, and other cleaning agents .

How palm oil milling machine works?

Palm oil is pressed and extracted with a series of phases so as to make sure the quality of final palm oil. Palm oil processing plant usually utilizes professional and efficient palm oil milling machines to deal with the production processes. The following are the typical steps of palm oil milling process.

Step 1. fresh fruit bunch (FFB) harvesting

Step 2. Threshing system

Step 3. Sterilization system

Step 4. Digesting system

Step 5. Palm oil extraction process (mechanical)

Step 6. Clarification

Step 7. The palm keener recovery stage

If you are interested in how palm oil milling machine works and the cost of related palm oil processing machinery, you can send email to info@palmoilmillplant.com directly. Or you can consultant with our senior engineers and specialized team with below contact details. You will get instant replies in the first time.

-

Dear Sirs,We are an investors who looking to purchase Palm Oil milling machine for our site in Trang Province (Thailand).

We would be appreciate if you could provide us the range of machine you have and its capacity/hour, FOB price and where could we see the operating machine of yours? -

Hi, is your raw materia palm fruit or palm seed? what's the desired processing capacity per day?

ABC Machinery is mainly specializing in manufacturing and exporting complete plant and euqipments of oil and fats plant.

For detailed info, pls kindly see our website: www.palmoilmillplant.com for more details.

We look forward to working with you soon.