High-yielding and quality palm oil is extracted from fresh palm fruit bunches, and milled through a cost-effective Palm Oil Milling Technology. The erstwhile cumbersome process of extracting palm oil is cumbersome, to say the least. It involved primary processes that were significantly time consuming and labor-intensive, such as, pounding the cooked bunch in large mortars with wide pestles. However, owing to the high demand for palm oil globally, and the advent of technological equipment, the old and traditional methods have given way to a new technological palm oil milling process. The entire structure is continuous and automated, and works cogently to produce palm oil of a high volume, and works to ensure high economical value from palm fruits. This mechanical operation is designed to improve milling efficiency, minimize labor interference, and enhance the quality of the output. (You may also like Palm Oil Business Plan >>)

High-yielding and quality palm oil is extracted from fresh palm fruit bunches, and milled through a cost-effective Palm Oil Milling Technology. The erstwhile cumbersome process of extracting palm oil is cumbersome, to say the least. It involved primary processes that were significantly time consuming and labor-intensive, such as, pounding the cooked bunch in large mortars with wide pestles. However, owing to the high demand for palm oil globally, and the advent of technological equipment, the old and traditional methods have given way to a new technological palm oil milling process. The entire structure is continuous and automated, and works cogently to produce palm oil of a high volume, and works to ensure high economical value from palm fruits. This mechanical operation is designed to improve milling efficiency, minimize labor interference, and enhance the quality of the output. (You may also like Palm Oil Business Plan >>)

New Technological Palm Oil Milling Process

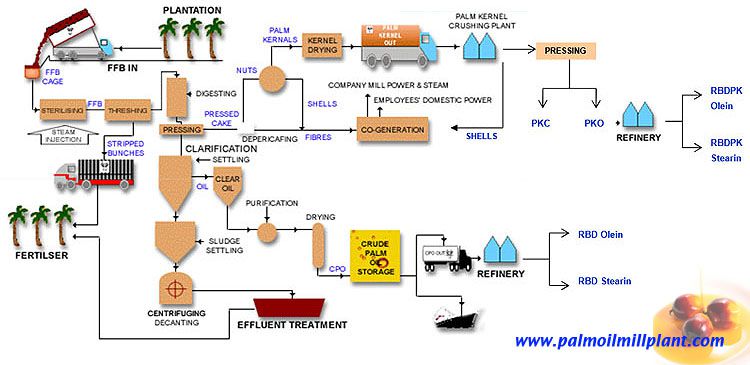

The primary process of new palm oil milling technology can be explained as follows:

Palm Oil Milling Process

- Choosing

Choosing the best quality fruit bunches gives the best palm oil that is of high consumable quality. The first process is identifying the bunches that would be able to withstand the high-pressure processes ahead.

Oil Palm Trees

Palm Oil Fruit Bunches Choosing

The reception of palm fruit bunches can also be a section for palm oil milling process. It involves weighbridges, FFBs unloading, fruit bunches reception. Palm fruit bunches reception system is typically designed for larges scale palm oil processing plant.

The fresh palm fruit bunches are first sterilized at high temperatures (145°C) through steam until the bunches are cooked and turn soft and mushy that would make them available for further processes. The sterilization ensures that the lipase is broken down, ensuring that the fat is not broken down into fatty acids, and prevents its build up. These cooked fruits then move to the mechanical thresher, which effectively separates the bunches from the fruit, enhancing the fruit to undergo the process that will yield the largest volume of oil.

The threshed bunch from the previous process gives the primary product at this stage, the fruits. These then go through the digester and thereby the screw palm oil press machine, affecting their molecular and structural integrity, enabling a higher output of oil. Being crushed and pressed, they release fibrous materials, which may subsequently be used for producing by-products, and thereby the kernels, which are fuel sources. (Related article about Palm Oil Milling Machine >>)

Once the primary crude palm oil is extracted, it is passed through filters where the oil is purified for consumption, and dried, where we get palm crude oil, the final product. The other by-products are either sludge or kernels from the cake fibers. For high quality palm oil, the palm oil refining process is also recommended to remove the useless and unhealthy substances in the crude palm oil, at the same time, to improve the color and smell of the final palm oil.

Science and technology have come a long way in making the highest possible consumables available to mankind. Pushing the best quality ingredients through the effective automated palm oil milling technology guarantees high volumes at good quality, which is cost-effective and offers tremendous time and labor savings.