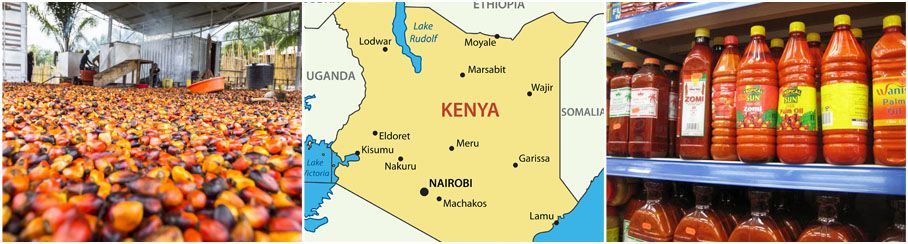

Palm Oil Production in Kenya

Trials and studies have shown that areas along the Equatorial region particularly the Western and Coastal regions of Kenya have very conducive conditions for the setting up of Palm Oil Factory. However, large scale production of palm oil is yet to take root in the country. A majority of Kenya's palm oil mills are run and owned by wealthy businessmen who are minting millions of dollars from this booming agribusiness venture. Even so, meeting the country's high demand of palm oil has been quite a challenge, which forces the country to spend close to $140 million annually on palm oil imports in a bid to meet this huge supply gap. The government has been trying to encourage farmers to set up palm oil mill plant on a small scale basis so as to increase the supply of palm oil as well as to help eradicate poverty. Kenya's government has also tried to come up with friendlier investment policies, such as reduced taxes in a bid to increase foreign investment in the country. This is aimed to promote invest palm oil investment in Kenya. (Latest Post: Cost of Setting up a Palm Oil Mill in Nigeria >>)

Palm Oil Processing in Kenya

Palm Oil Refinery Mill Setup Cost in Kenya

Some of the advantages that have been linked with the setting up palm oil refinery mills in Kenya include:

- Availability of a Ready Market

The country can only supply a third of its palm oil needs, which means potential investors have the opportunity to help close in on this huge supply gap.

- Availability of a Ready Labor

Majority of the people residing in Kenya's Western region live under impoverished conditions due to high unemployment rate. For this reason, the region has plenty of readily available labor which sets aside the need to outsource labor to work on the palm oil processing plant.

- Higher Oil Yield of Palm Oil

Palm oil plants are a very profitable agribusiness venture owing to their high annual yields. According to reports, their yield is much higher their counterparts: sunflower and soy beans. The average annual yield per hectare is estimated to be over 10 tonnes of palm oil which is even higher than leading cash crops like tea and coffee.

- Minimal Competition of Palm Oil Mill

The production of palm oil in Kenya currently has very Minimal Competition owing to the fact that the large scale palm oil production has not been fully tapped into. As earlier mentioned, the current palm oil mills can only meet a third of the country's demand.

New Palm Oil Refining Equipment Process

- Degumming

The soluble impurities not only affect the stability of palm oil, but also affect the process effect of oil refining and deep processing. In the process of alkali refining, oil will promote emulsification, increase the difficulty of operation, increase the consumption of refining and adjuvant, and reduce the quality of soapstock; In the decolorization process, increase the amount of adsorbent consumption, reduce the decolorization effect.

The method we use in actual production is hydration degumming. The basic principle of oil hydration degumming is to use the hydrophilicity of colloidal impurities such as phospholipids, add a certain amount of electrolyte solution to oil, make the colloidal impurities absorb water, coagulate and separate from oil. The pectin is dominated by phospholipids. When there is little water, the phospholipids in the oil dissolve in the salt structure and disperse in the oil. When the water increases, it absorbs water and increases in volume. The colloidal particles attract each other and form larger micelles, which can be separated from the oil due to the difference in specific gravity.

- Deacidification

There is always a certain amount of free fatty acids in vegetable oils, including palm oil, and the amount depends on the quality of the oil. The immaturity of seeds and the high damage of seeds are also the reasons for the high acid value oil, especially under the condition of high water content, which is very unfavorable for the preservation of oil, which will increase the free acid content, reduce the quality of oil, and worsen the edible quality of oil.

The common method of palm oil deacidification is alkali refining. Caustic soda can neutralize most of the free fatty acids in crude palm oil, and the generated sodium salt is not easy to dissolve in the oil, becoming floccus and settling. The resulting sodium salt is a surfactant that can carry considerable amounts of other impurities into the precipitate, such as proteins, mucus, pigments, phospholipids, and substances with hydroxyl and phenolic groups. Even suspended solid impurities can be carried down by flocculent soap clumps. Therefore, alkali refining has a comprehensive effect of deacidification, degumming, solid impurity and pigment removal.

- Decoloring

The pigment composition in vegetable oil is complex, mainly including chlorophyll, carotene, flavonoid pigment, anthocyanin and the decomposition products of some sugars and proteins. Palm oil decoloration usually uses adsorption decoloration. The principle of adsorption decolorization is to use adsorbent with strong adsorption power to adsorb pigment and other impurities in hot oil. The adsorbent can be filtered and removed at the same time to remove the pigment and impurities adsorbed, so as to achieve the purpose of decolorization and purification.

- Deodorization

All kinds of vegetable oil have their own unique flavor and taste. In addition, the palm oil deacidification and decolorization process will also have a trace of aldehydes, ketones, hydrocarbons, low molecular fat, glycerol phenol oxides and clay, residual solvent smell, etc.. Deodorization process is to remove these bad odors and substances.

Tips on Palm Oil Refinery Setup in Kenya

Just like any other investment opportunities, investing in palm oil refinery mill in Kenya can have its fair share of ups and downs. So as to limit the 'downs' side of it the following set of tips could come in handy if you plan on taking on this kind of investment.

Small Palm Oil Refiney Mills in Kenya

Small palm oil refinery mill designed by ABC Machinery is specially developed and produced according to the actual situation in Africa. It is very popular in Indonesia, Nigeria, Liberia, Zambia, Kenya, South Africa and other countries and regions. Small palm oil refining equipment belongs to intermittent (batch type) oil refining, which has all the functions of large and medium intermittent palm oil refinery plant and is superior to large and medium refining equipment. It can produce national standard, second, third and fourth grade oil at the same time. Small palm oil refinery mill in Kenya has the advantages of multi-purpose refining, convenient installation and transportation, small occupation area, few operators, and energy saving. Mostly important, it is requires low invest cost. If you have any questions or advice about starting palm oil refinery mil in Kenya, please contact us directly, we will get back to you soon!