Have you ever dreamed of owning exclusive "Palm Oil Refining Technology" and becoming a leading figure in the palm oil milling industry? In this column, we will unveil the unique art of palm oil refining, from raw materials to the finished product, delving into the secrets of creating high-quality products. Join us on this journey to master the craft and seize the opportunity to excel in the market.

Unlocking the Secrets of Excellent Palm Oil: The Palm Oil Refining Technology

As one of the world's most widely produced edible oils, palm oil boasts a rich history. However, the past methods of palm oil refining might not have been perfect. Thanks to technological advancements, modern refining techniques present a fresh avenue for the palm oil industry to prosper.

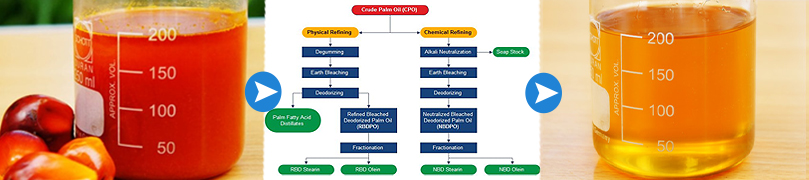

From Crude Palm Oil to Refined Palm Oil

There are roughly two methods for refining palm oil, each with their own pros and cons. We'll choose the best one based on your needs and situation. Your satisfaction is our main focus as we aim for perfection in the palm oil refining process design.

Physical Refining Method VS Chemical Refinery Techology

Palm oil physical refining involves removing impurities, moisture, and volatiles through physical processes while preserving natural nutrients.

The physical refining for palm oil lies in preserving natural nutrients without the need for chemical additives. However, it may not entirely remove acidity and pigments.

Chemical refining for plam oil utilizes acid-base neutralization and bleaching to enhance oil quality and stability.

Chemical refining can effectively remove acidity and pigments, but it may lead to some loss of nutrients and requires the use of chemical auxiliaries.

Crucial Steps in Palm Oil Refining Solutions

To stand out in this fiercely competitive market, possessing exceptional palm oil refining technology becomes paramount. The process of palm oil refining is far from simple; it involves a series of critical steps. From deacidification and decolorization to impurity removal, each step significantly influences the final product's quality.

- Degumming: This initial stage involves the removal of gums, phospholipids, and other impurities from the crude palm oil.

- Neutralization: In this step, free fatty acids present in the crude oil are eliminated through a process known as neutralization.

- Bleaching: The bleaching stage aims to remove pigments, residual impurities, and undesirable odors from the oil.

- Deodorization: The final stage of palm oil refining is deodorization. It involves heating the oil under high temperature and vacuum conditions while passing steam through it.

The refined palm oil obtained from this process is now suitable for a wide range of applications, including food, cosmetics, and biofuels. It boasts improved stability, extended shelf life, enhanced sensory attributes, and compliance with safety requirements.

Gateway to Success: Practical Cases of Palm Oil Refining from ABC Machinery

While theoretical guidance is essential, practical cases serve as the ultimate test of technological value. In this column, we will conduct in-depth studies of real-life cases, exploring how palm oil refining techniques are applied in different enterprises. By drawing from successful experiences and lessons learned, you'll be better equipped to navigate market challenges and create your own success story.

Sucessful Palm Oil Refining Projects around the World

Mastering palm oil refining technology is akin to mastering alchemy, transforming ordinary fats into precious "green gold." In the "Palm Oil Refining Technology" column, we offer a panoramic view of the industry, unlocking the secrets of refinement, and opening the door to success. Let's journey together, building a bright future!Here are some projects setup by ABC Machinery, if you have any interests in buildig palm oil refining plant, welcome to contact us now!