Palm oil is the vegetable oil with the largest production, consumption, and international trade volume in the world. Indonesia, as the world's largest palm oil producer, occupies an important position in the global palm oil market.

After seeing this business opportunity, some investors planned to build a palm oil processing factory to bring more benefits to themselves. But how do you build a profitable palm oil processing plant from scratch? This is a problem for investors.

Start Profitable Palm Oil Processing Business in Indonesia

In this blog, palm oil processing machine manufacturer ABC Machinery will detail the steps for investors to set up a palm oil factory.

Essential Steps for Setting Up Palm Oil Mill in Indonesia

The steps for setting up a crude oil milling plant from scratch include feasibility study, factory site selection and construction, Process flow design, equipment selection, workshop equipment layout design, equipment installation, environmental protection, project budget cost analysis, etc...

How to proceed at each step and what issues need to be paid attention to?

Conduct A Thorough Feasibility Study for Palm Oil Business

First, it is necessary to fully understand Indonesia’s local palm oil industry policies, market demand and competition landscape. Pay attention to collecting data such as land cost, labor force, and raw material prices to evaluate palm oil production costs. Consider environmental regulations and social responsibilities to ensure sustainable operations. At the same time, risk assessment and market prospect analysis are also crucial.

Choose An Optimal Location for Palm Oil Mill Plant Site

- Convenient transportation: First, choose an area with convenient geographical location and convenient transportation, which is conducive to the transportation of raw materials and finished products.

- Abundant labor resources: Second, ensure there are sufficient labor resources nearby to meet production needs.

- Comply with local policies and regulations: At the same time, understand local government policies and regulations to ensure that the site selection meets relevant requirements.

Design The Palm Oil Production Process Flow Effectively

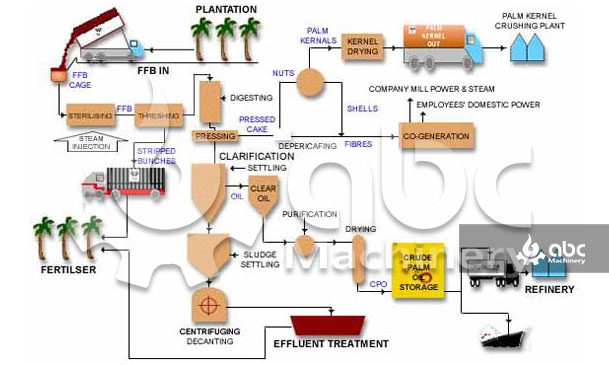

Palm oil mill process flow design is the design of the entire production process from raw materials to finished products. It combines the production sequence and the equipment used and presents it in the form of diagrams. Due to the particularity of the raw materials, the processing process of palm oil is different from that of other types of oil.

Carefully Select the Appropriate Palm Oil Processing Equipment

When selecting palm oil processing machine, the process requirements and the specifications, performance, technical characteristics, and usage conditions of various equipment must be fully considered. When selecting equipment, generally determine the type first and then consider the capacity.

Equipment commonly used in palm oil mills include: 表格

| Machinery | Brief Introduction |

|---|---|

| Palm Fruit Sterilizer | Use water vapor or water to kill bacteria that promote oxidationuse water vapor or water to kill bacteria that promote oxidation |

| FFB Thresher | Strips palm fruit from the bunches |

| Digester | Heats and crushes the palm flesh to increase oil yield |

| Palm oil extraction machine | Include manual presses, screw presses (most commonly used), and hydraulic presses. |

How to calculate the number of required shaping equipment?

For shaping equipment, you only need to select the appropriate model according to process requirements and output, or calculate and determine the number of units required.

n=G/g

G---- Material handling capacity of a certain process, t/d

g-----Production capacity of a certain equipment, t/d

n-----the adjacent larger integer

Design The Workshop Layout with Thoughtful Considerations

In the production workshop of an Indonesian palm oil factory, reasonable equipment layout is crucial to improve production efficiency and operational safety. The final layout design should take into account the specific size of the palm oil mill plant, the palm oil production processes and local safety regulations in Indonesia. Work with plant construction professionals and safety experts during the design process to ensure the layout meets best practices and standards.

Learning More Details: Palm Oil Mill Factory Layout Design>>

Implement Effective Environmental Protection Measures

Pollution that may be caused by palm oil mills are effluent, sludge, exhaust, and noise. All of these pollutants have to be treated and controlled by installing the regulations of the local authorities.

Conduct A Cost Analysis for Palm oil Manufacturing Project

Conducting a budgeted cost analysis for a palm oil factory in Indonesia mainly includes cost of equipment, labor, raw materials, transportation, construction and operation. When conducting a cost analysis, the specific value of each cost item is carefully estimated and possible variations are considered. At the same time, a reasonable budget plan is developed to ensure that all aspects of production and operations can be covered to improve the long-term viability of the plant.

Learning More Details: Cost of Setting Up A Palm Oil Factory>>

All the above mentioned are just a brief mention, if you have any doubts, check out the other articles in the column or contact our team directly for professional answers!

Choosing the Right Partner for Your Palm Oil Business Success

Palm Oil Pioneers: 20 Years of Industry Mastery in Specialized Equipment Manufacturing and Complete Plant Construction

The picture is only a partial display, for more details, please click on the title of the picture to get more information.

ABC Machinery a specialized company with more than 20 years of experience in manufacturing palm oil equipment and constructing the whole process of mills.

The quality of our equipment meets the highest standards, ensuring that your production line runs efficiently and reliably. In addition, we offer a full range of services from planning and design to equipment manufacturing and plant construction. With our industry-leading experience, we provide our customers with excellent solutions to help the palm industry take off.